| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

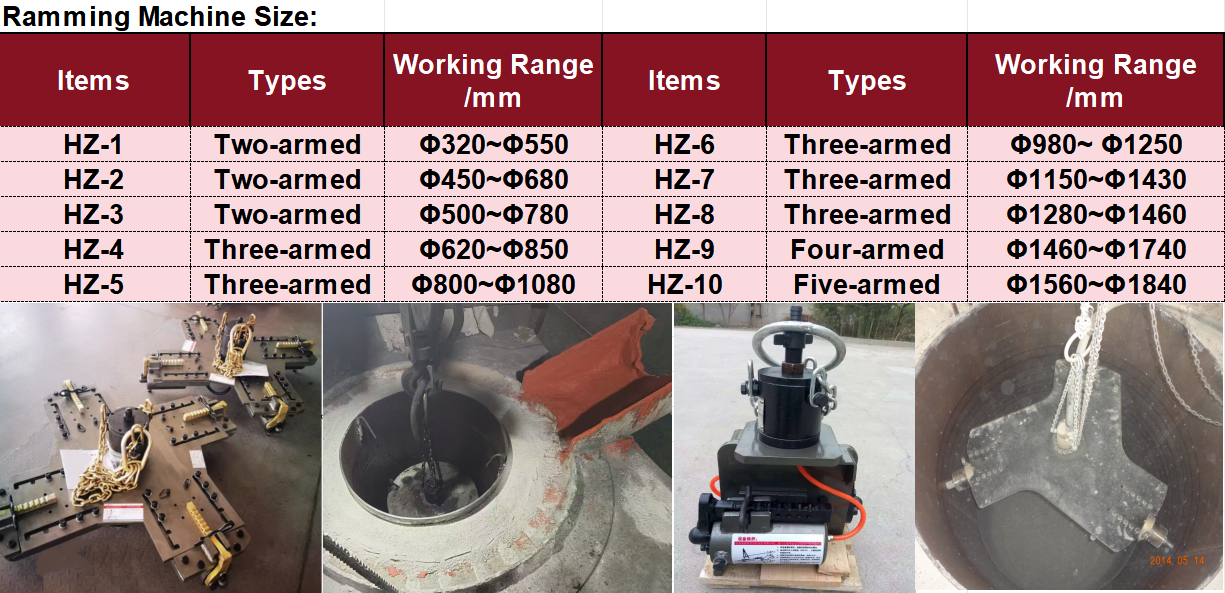

| Brand Name : | HXS |

| Model Number : | HZ |

| Certification : | ISO9001:2015 |

| Payment Terms : | L/C, D/A, D/P, T/T |

| Supply Ability : | 500 sets per month |

| Delivery Time : | 8-15 working days |

The main function of the pneumatic ramming machine is to improve the compactness and uniformity of the furnace lining, while reducing labor intensity and shortening the furnace building time.

Compared with traditional electric vibrator and manual furnace building tools, pneumatic ramming machines have the following advantages:

Improve tightness and uniformity: The pneumatic ramming machine

can effectively vibrate various points in the furnace lining

material to make the top and bottom of the furnace lining

consistent, avoiding uneven tightness caused by uneven strength

during manual knotting.

Reduce labor intensity: The use of pneumatic ramming machines can

greatly reduce labor intensity, especially for large-tonnage

induction furnaces, which can greatly improve the quality of

furnace lining.

Shorten the furnace building time: The pneumatic ramming machine

can significantly shorten the furnace building time, especially for

medium and large-tonnage induction furnaces. The manual knotting

method is very cumbersome and the effect is not ideal, but the

pneumatic ramming machine can complete the knotting quickly and

conveniently.

In addition, the method of using the pneumatic ramming machine is

relatively simple. You only need to lift the pneumatic ramming

machine into the crucible with a automatic crane, and then connect

the air source to realize automatic knotting, which is convenient

to operate.

|