| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HXS |

| Model Number : | HM |

| Certification : | ISO9001:2015 |

| Payment Terms : | L/C, D/A, D/P, T/T |

| Supply Ability : | 2000 ton per month |

| Delivery Time : | 5-8 working days |

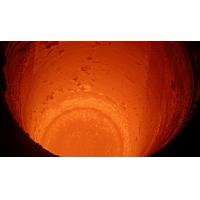

In the competitive world of metal casting, cost-effectiveness is crucial. Dry ramming mix offers several economic advantages that can help foundries reduce costs and improve profitability.

The longer lifespan of dry ramming mix means fewer relining cycles, reducing downtime.

This allows foundries to operate more efficiently and meet production deadlines.

Dry ramming mix's resistance to wear and tear minimizes the need for frequent repairs.

This translates to lower maintenance costs and higher profitability.

The low thermal conductivity of dry ramming mix reduces heat loss, lowering energy consumption.

This can result in significant cost savings over time.

A cast iron foundry in China adopted our dry ramming mix and achieved:

30% reduction in relining costs.

20% lower energy bills.

Increased production output due to reduced downtime.

Dry ramming mix is not only a high-performance material but also a cost-effective solution for foundries. By reducing downtime, maintenance costs, and energy consumption, it helps foundries improve their bottom line.

|