| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HXS |

| Model Number : | HS; HA |

| Certification : | ISO9001:2015 |

| Payment Terms : | L/C, D/A, D/P, T/T |

| Supply Ability : | 2000 ton per month |

| Delivery Time : | 5-8 working days |

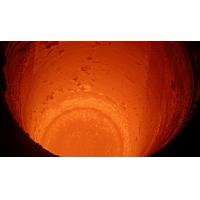

When it comes to furnace linings, foundries have a choice between dry ramming mix and traditional refractory materials such as bricks, castables, and plastics. In this article, we compare these options and explain why dry ramming mix is often the superior choice.

Application: Applied in a dry or semi-dry state and compacted using ramming tools.

Advantages:

Uniform density and consistency.

Excellent thermal shock resistance.

Longer lifespan due to resistance to erosion and cracking.

Easy to repair and maintain.

Disadvantages:

Requires skilled labor for proper installation.

Bricks:

Advantages: Easy to install, readily available.

Disadvantages: Prone to cracking under thermal stress, shorter lifespan.

Castables:

Advantages: Can be poured or pumped into place.

Disadvantages: Longer curing time, lower thermal shock resistance.

Plastics:

Advantages: Flexible and easy to mold.

Disadvantages: Limited to lower-temperature applications.

Performance: Offers superior thermal stability and resistance to wear.

Cost-effectiveness: Reduces downtime and maintenance costs.

Versatility: Suitable for a wide range of metals and casting processes.

A foundry in India replaced their traditional brick linings with our dry ramming mix. The results included:

40% reduction in relining frequency.

25% lower energy costs.

Improved casting quality due to better heat distribution.

While traditional refractory materials have their place, dry ramming mix offers significant advantages in terms of performance, cost-effectiveness, and versatility. For foundries looking to improve efficiency and reduce costs, dry ramming mix is the clear choice.

|