| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HXS |

| Model Number : | HA |

| Certification : | ISO9001:2015 |

| Payment Terms : | L/C, D/A, D/P, T/T |

| Supply Ability : | 2000 ton per month |

| Delivery Time : | 5-8 working days |

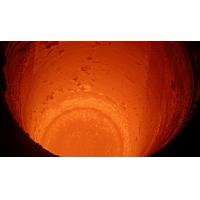

Proper installation is crucial to maximizing the performance and lifespan of dry ramming mix. In this article, we provide a step-by-step guide to installing dry ramming mix in foundry furnaces.

Clean the furnace shell to remove any debris or old refractory material.

Ensure the surface is dry and free of moisture.

Use the dry ramming mix as supplied; no additional water or binders are required.

For large installations, consider using a mechanical mixer to ensure uniformity.

Apply the dry ramming mix in layers, typically 50-100 mm thick.

Compact each layer using pneumatic or manual ramming tools.

Allow the lining to cure naturally for 24-48 hours.

Gradually heat the furnace to remove any residual moisture.

Regularly inspect the lining for signs of wear or damage.

Perform minor repairs as needed to extend the lining's lifespan.

Use the right tools and equipment for compaction.

Follow the manufacturer's guidelines for layer thickness and curing times.

Train your staff on proper installation techniques.

Proper installation of dry ramming mix is essential for achieving optimal performance and longevity. By following these steps, you can ensure a durable and efficient furnace lining that meets your foundry's needs.

|